the most innovative portable truing system in the world

one-of-a-kind portability and precision

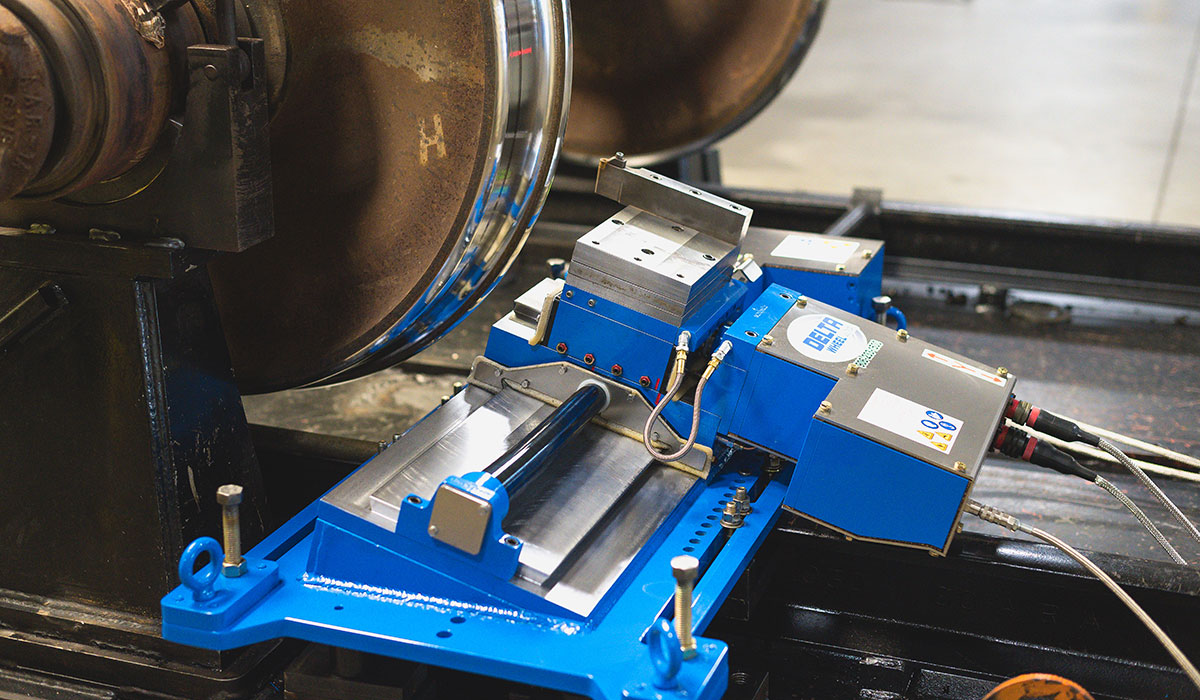

Nothing comes close to Wheel Hog practicality. When full-scale service center truing is not an option, Wheel Hog easily delivers the truing you need to keep your fleet service undisrupted and on track. Saving time and money with the affordable and portable Wheel Hog.

Wheel truing pros call it “Wheel Hogging.” We call great, portable truing… Wheel Hog!

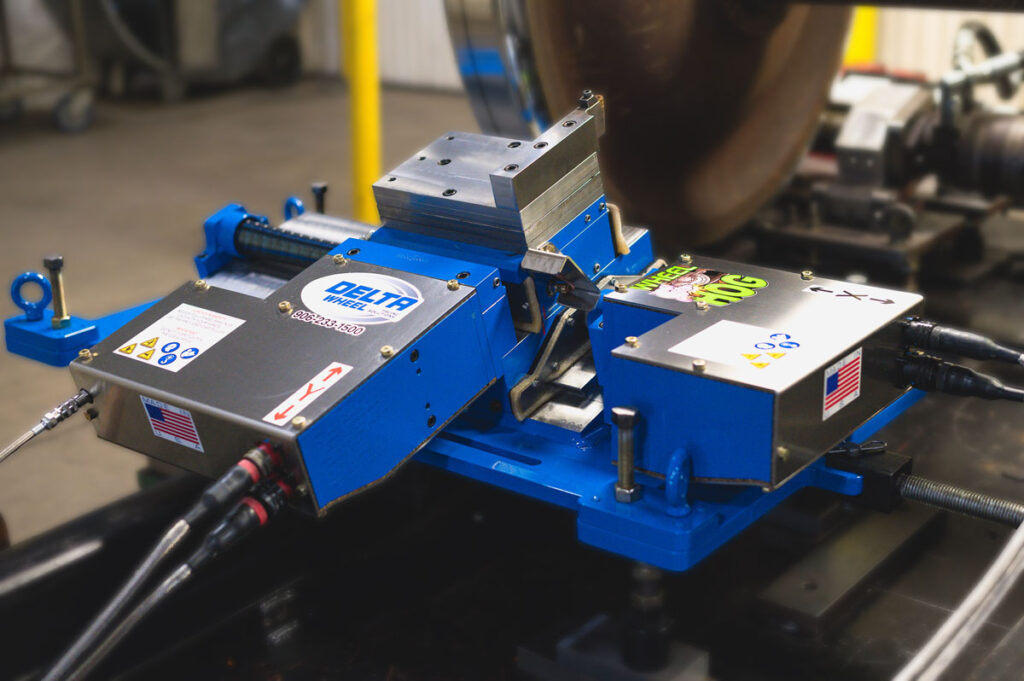

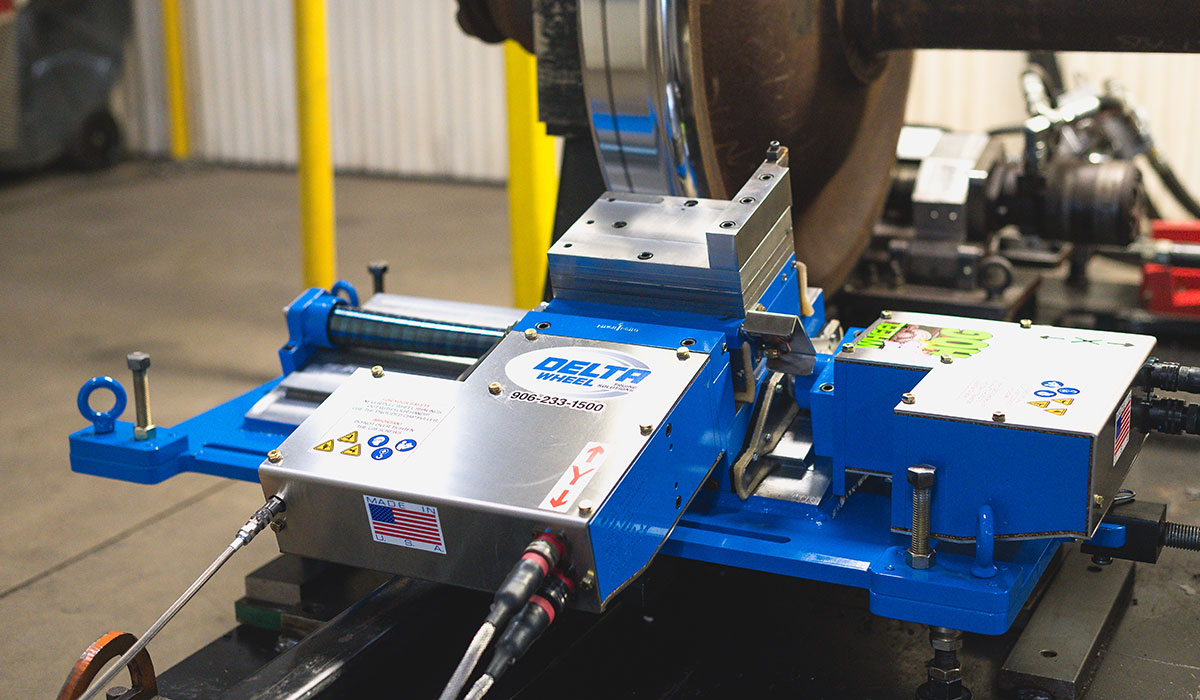

Wheel Hog key performance and safety features

Click on each blue box to learn more about the feature.

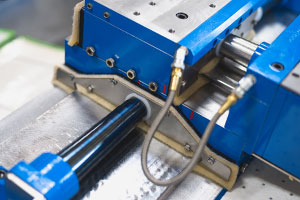

11 high-quality lubrication injectors keep all dovetails and lead screw nuts lubricated during operation.

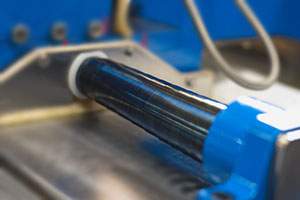

Protects Y-Axis lead screw from dirt and debris during operation and when not in use.

- Houses oil-feed connections for filter unit and oil distribution system.

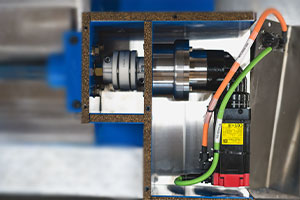

- High-performance motor and reducer that provide maximum torque to lead screw drive assembly.

- Direct-drive disc coupler delivering zero backlash for continuous high-performance.

- 1/2” thick protective enclosure with high-density seal which keeps dirt and debris out

Cleans dovetail machine surfaces, wiping away dirt and debris during operation.

Easy to connect, durable molded construction, built to last

Protects X-Axis lead screw from dirt and debris during operation and when not in use.

- High-performance motor and reducer that provide maximum torque to lead screw drive assembly.

- Direct-drive disc coupler delivering zero backlash for continuous high-performance.

- 1/2” thick protective enclosure with high-density seal which keeps dirt and debris out.

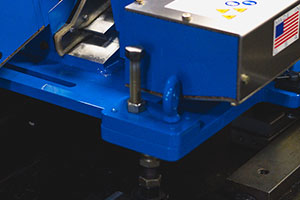

Heavy-duty weldment made from 1″ plate

precision wheel truing simplified

Wheel-related service disruptions can easily cost rail operations thousands of dollars per incident, including downtime. This includes time waiting for repairs, the cost of shipping wheel sets or moving entire locomotives to reconditioning facilities, outsourcing mobile repair contractors, lost revenue from canceled train departures, and even Federal Rail Administration (FRA) fines.

advantages

- Use in work shop or out in the field

- Easy set-up and operation

- Low Profile Portable CNC Locomotive Wheel Lathe allows minimal brake rigging removal while giving more access room on 6 axle locomotives

- FANUC iPendant eliminates the need for the operator to be under the locomotive during operation

- CNC controlled for accurate profile with a superior finish

- Custom profiles easily available

- Maximum wheel life with minimal wheel loss

- Eliminates the cost associated with shipping the wheel sets or an entire locomotive to a reconditioning facility

- Reduces labor and cost

- Bottom line – cost savings and quick return on investment

Patented In: United States, Russia, United Kingdom, France, India and Germany

Ultimate in-the-field wheel truing

Wheel Hog is busy operating in hundreds of locations around the world. Saving time and money, keeping fleets on track and operating.