Made to serve. Built to last.

Every Part, Every Component, Made to Perform True

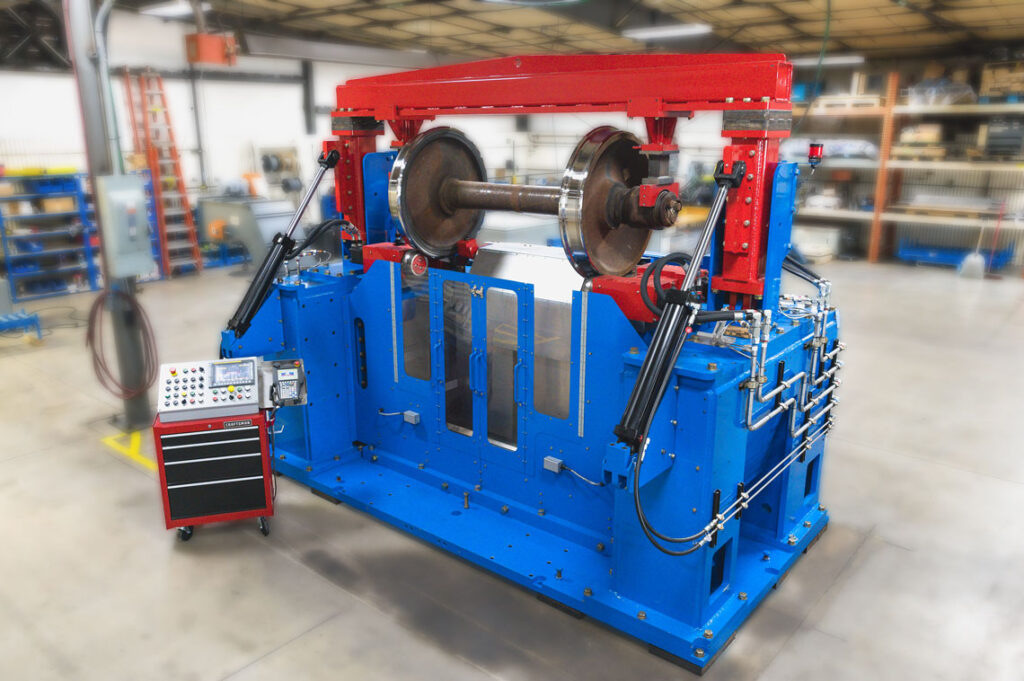

Rail systems around the world depend on Delta Wheel Truing Solutions to deliver years of precision results with dependability. Every part and component of our stationary wheel lathe systems are designed, installed and tested by our team on every unit we build.

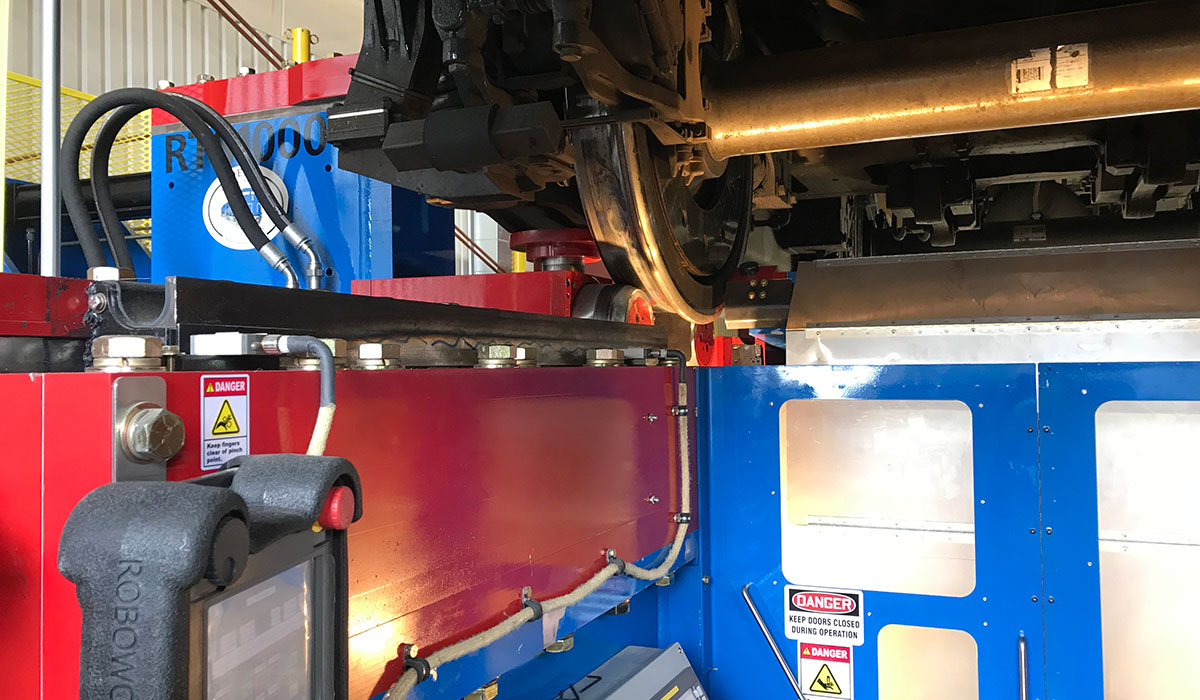

Key Precision & safety Features Built-In

Click on each blue box to learn more about the feature.

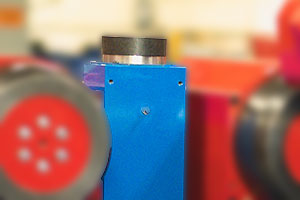

- Contacts the end of the axle during operation to stop the axle from moving from left to right.

- Ensures precise wheel profile during lathe truing process.

- 4 drive rollers take over and rotate the wheel during the truing process. Rollers assist in lifting and overall stabilization of the vehicle.

- Rollers deliver tractive effort/adhersion to rotate wheels at a consistent speed during truing for maximum precision and accuracy from wheel to wheel.

- One of 3 components that securely hold the vehicle in place.

- Supports the bottom of the journal box, so there is no movement of the axle during the truing process.

Designed for simple and intuitive use anywhere in the world.

Controls ensure that all operations are completed step-by-step in the correct sequence.

Smart and logical panel configuration divided into separate operating functions:

- Operating functions

- Wheel drive functions

- Lathe functions

Color-coded to show the stage of operation at any time:

- Green – Operating

- Yellow – Operation needs to be completed

- Red – Operation completed

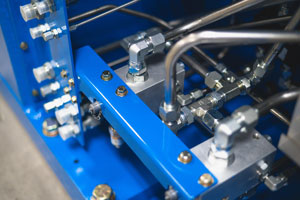

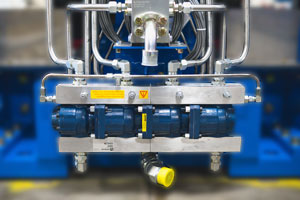

Valves ensure that cylinders holding vehicle are locked in place before, during and after lathe operation. Cylinders won’t extend or retract without power and commands being applied.

Ensures the cylinders lifting the vehicle during operation cannot retract during power loss.

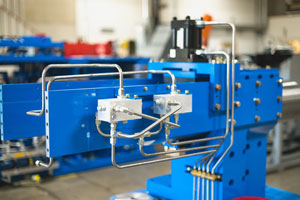

Like a true 4-wheel drive system, the quad divider provides equal flow to each drive roller of the machine, ensuring constant traction to the vehicle wheel. This prevents slippage during the truing process.

- Contacts the back side of the wheel. Works in tandem with axle centers to prevent lateral movement of the wheels during the truing operation.

- Delivers maximum accuracy wheel to wheel.

hydraulic power unit Features

Click on each blue box to learn more about the feature.

Maintains even and precise temperature of oil during all system operations.

- Feeds oil to hydraulic drives and auxiliary hydraulic functions independently.

- Allocates dedicated oil supply to all system hydraulic functions.

Filters oil from all hydraulic cylinder functions.

- Motor circuit return filter

- Motor circuit high-pressure filter

Feature-filled model options

The Delta Wheel Truing Solution’s Stationary RTS1000 Under-Floor Wheel Lathe and RTS2000 Above-Floor Wheel Lathe are precise, easy to operate machines that are designed with the latest technology utilizing Fanuc CNC Controls (Main Control and Hand Pendant) with lifetime support! The design of the Delta’s wheel truing systems allows for straightforward installation, easy operation with user-friendly controls, and long service life is the result of the heavy-duty construction. Delta Wheel Truing Solutions is Buy America compliant!

advantages

- Easy installation

- User-friendly set-up and operation

- Safe-keeps operators away from razor sharp shavings

- Takes approximately 30-45 minutes to re-profile a wheel set

- CNC controlled for accurate profile with a superior finish

- Custom profiles easily available

- Maximum wheel life with minimal wheel loss

- Eliminates the cost associated with shipping the wheel set to a reconditioning facility

- Reduces labor and cost

- Bottom line, cost savings and quick return on investment

models

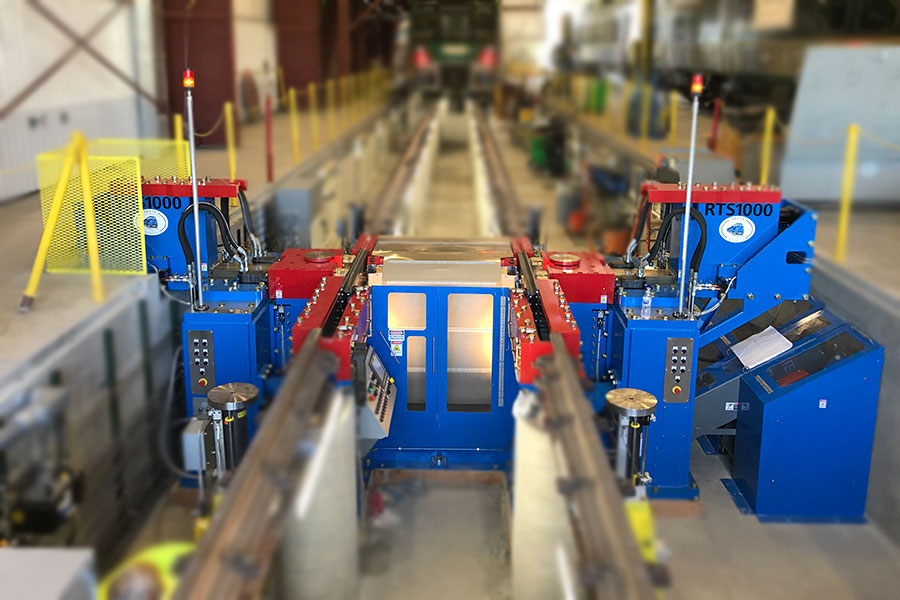

RTS 1000

Under-Floor Wheel Lathe

The RTS1000 Under-Floor Wheel Lathe supports freight locomotives, passenger vehicles, trucks/bogies, COMBO’s and single wheel sets.

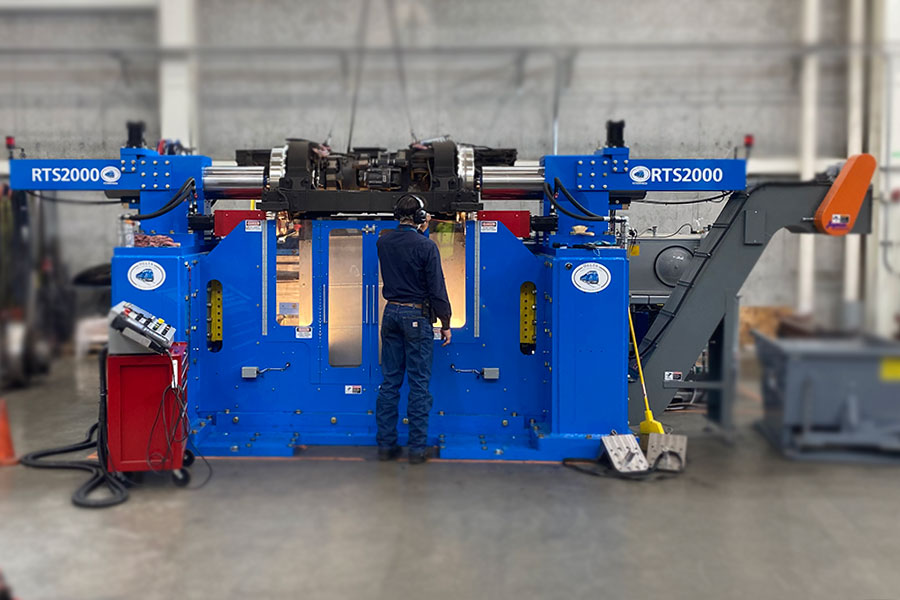

RTS 2000

Above-Floor Wheel Lathe

The RTS2000 Above-Floor Wheel Lathe will support trucks/bogies from freight locomotives, passenger vehicles, COMBO’s and single wheel sets.

High-Performance Customization To Meet Your Needs

Delta Wheel in-floor and above floor wheel lathes are busy at work right now, all over the world.

Customized options are available or can be designed!